Since the reliability of a process step is the yield of that process step when quality is the performance metric, this formula then becomes: RTY= (Y1) (Y2) (Y3) (Y4) … (Yn) where Y is the yield (proportion good) for each stepįor example, a four-step process has a yield of 0.98 in step 1, 0.95 in step 2, 0.90 in step 3, and 0.80 in step 4.

HOW TO CALCULATE PPM SERIES

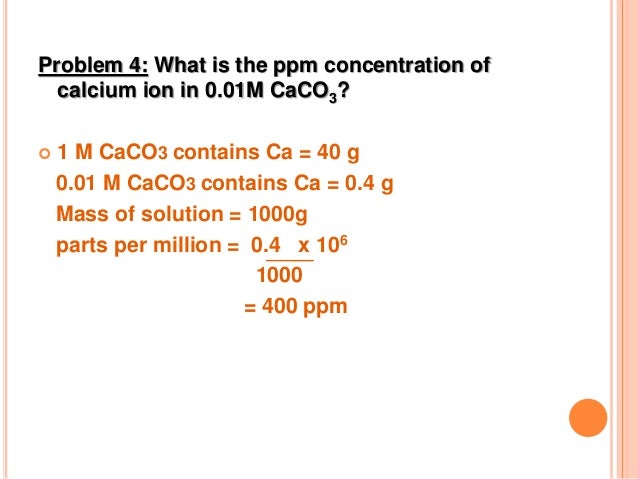

The reliability formula for a system in series with n process steps is: Rs = (R1) (R2) (R3) (R4) … (Rn) This requires mapping out a process to determine how many steps it involves. RTY (also known as the First Pass Yield) measures the probability (or percentage of time) that a manufacturing or service process will produce a defect-free unit. PPM is arrived at by simply taking the number of defective units in a same size, dividing that number by the total sample size, and multiplying by 1 million.įor example, a sample of 50 cards found that three are defective. Again, using the car scenario, the PPM would include the total number of defective cars – cars determined to be too flawed to be sold – per every 1 million cars manufactured.

The PPM represents the number of defective units per 1 million units. The goal is to reach 3.4 defects per 1 million opportunities. It’s also possible to translate DPMO to a Six Sigma level. If 10 forms are sampled and 26 defects are found in the sample, the DPMO is: The formula for calculating DPMO is as follows.įor example, consider a form that contains 15 fields of information. In other words, how many times did you have a flaw or mistake (defect) for every opportunity there was to have a flaw or mistake. This represents a ratio of the number of defects in one million opportunities. It’s found by dividing the total number of defects found by the number of units.įor example, if 30 units are produced and a total of 60 defects have been found, the DPU equals 2. Defects Per Unit (DPU)ĭPU measures the average number of defects per every product unit. Each of these opportunities has the potential of having a defect. Opportunities represent everything that goes into making a unit – materials, labor, delivery, etc. It can contain many defects and be found to be defective. A unit is the final product delivered to a customer. Again, using the car scenario, this means that 10 cars can have a maximum 10 defective units, because each car represents one unit.Īnother way to look at this is opportunity vs.

A car also contains many different areas that are assembled to create a finished vehicle. For example, a car is one finished unit in a process.

0 kommentar(er)

0 kommentar(er)